Mapping the Metallic Landscape: A Comprehensive Guide to Metallography

Related Articles: Mapping the Metallic Landscape: A Comprehensive Guide to Metallography

Introduction

With great pleasure, we will explore the intriguing topic related to Mapping the Metallic Landscape: A Comprehensive Guide to Metallography. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Mapping the Metallic Landscape: A Comprehensive Guide to Metallography

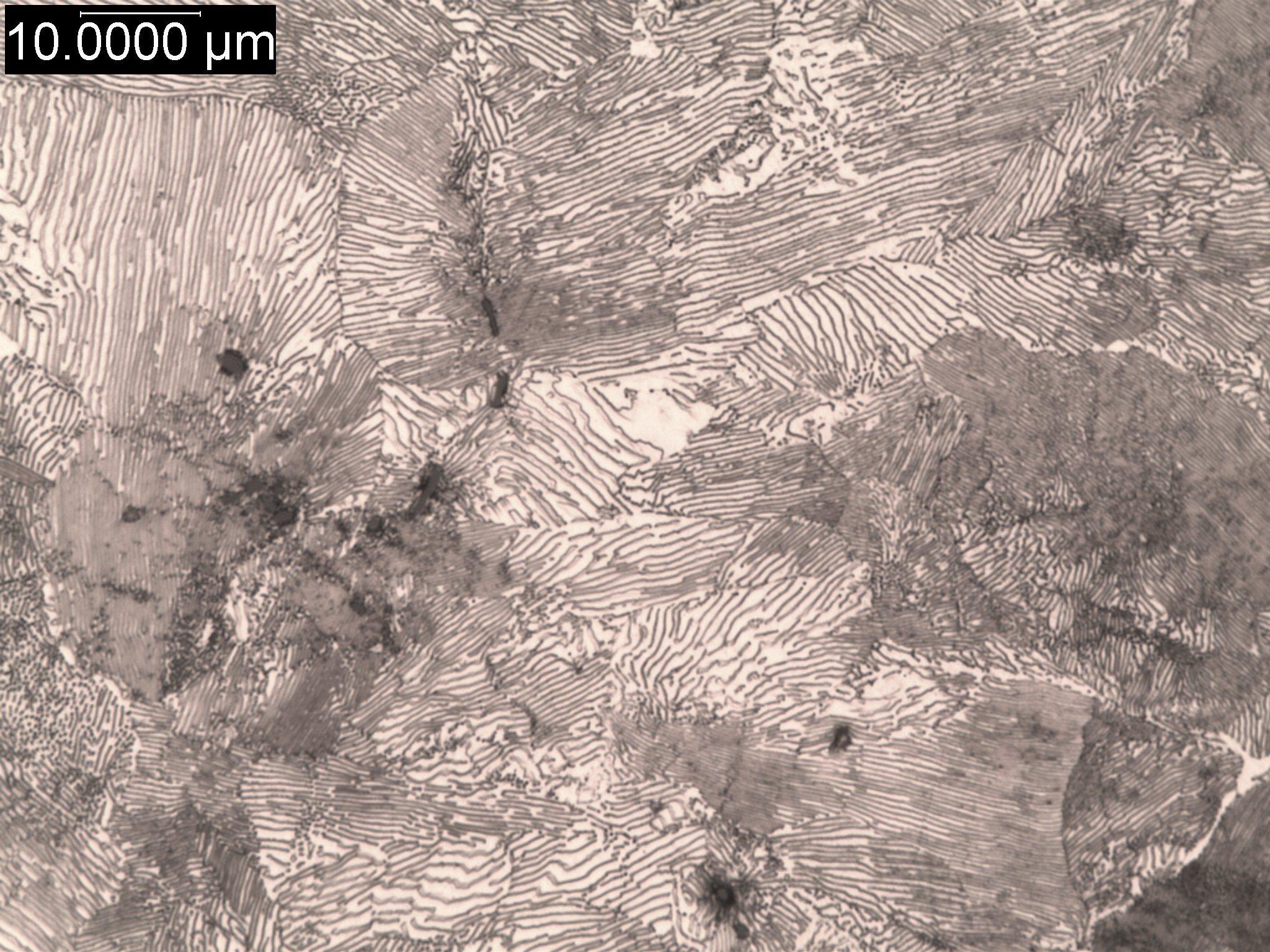

Metallography, the study of the structure and properties of metals, is a cornerstone of materials science and engineering. This field relies heavily on the analysis of metallographic specimens, which are carefully prepared and examined under microscopes to reveal the intricate details of their internal structure. A key tool in this endeavor is the metallographic map, a visual representation of the microstructure of a metal or alloy.

Understanding the Metallographic Map

A metallographic map, also known as a microstructural map, is a detailed visual representation of the spatial distribution of different phases, constituents, and features within a metal sample. It is essentially a "map" of the microstructure, providing a comprehensive overview of the material’s internal organization.

Construction and Interpretation

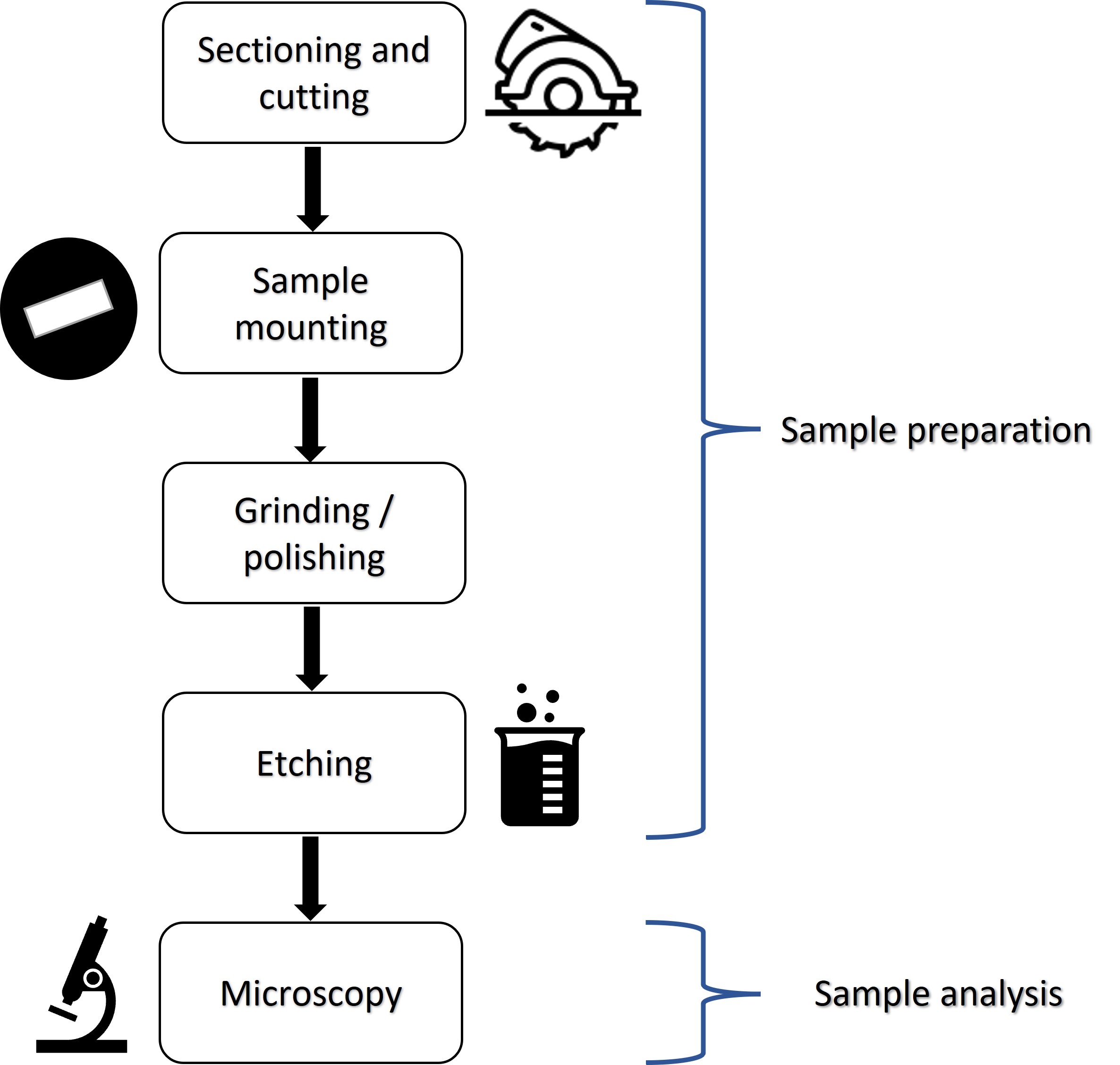

The creation of a metallographic map involves several steps:

-

Sample Preparation: A small, representative piece of the metal is carefully cut and mounted. This is followed by grinding and polishing to create a smooth, mirror-like surface.

-

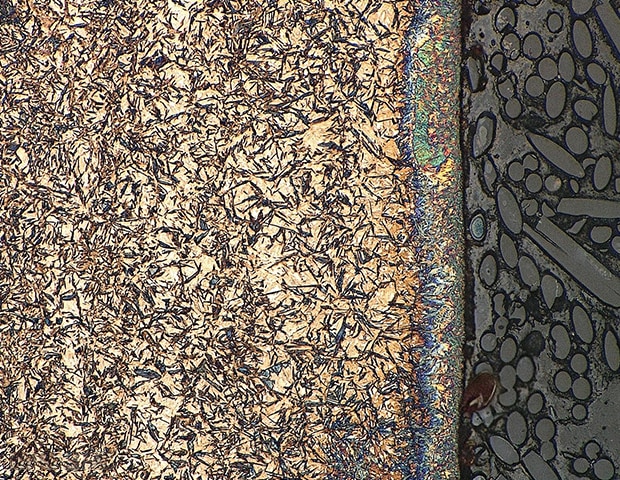

Etching: The polished surface is treated with a chemical etchant, which selectively attacks different phases or constituents of the metal. This etching process reveals the microstructure by creating variations in surface reflectivity, allowing different features to be distinguished under a microscope.

-

Microscopic Examination: The etched surface is then examined under a light microscope, often using polarized light to enhance contrast. The image is captured, either digitally or by drawing, to create the metallographic map.

-

Analysis and Interpretation: The map is then analyzed to identify the different phases present, their distribution, grain size, shape, and any defects or imperfections. This analysis provides crucial insights into the material’s properties, including its strength, ductility, toughness, and corrosion resistance.

Types of Metallographic Maps

Metallographic maps can be classified based on the type of information they represent:

-

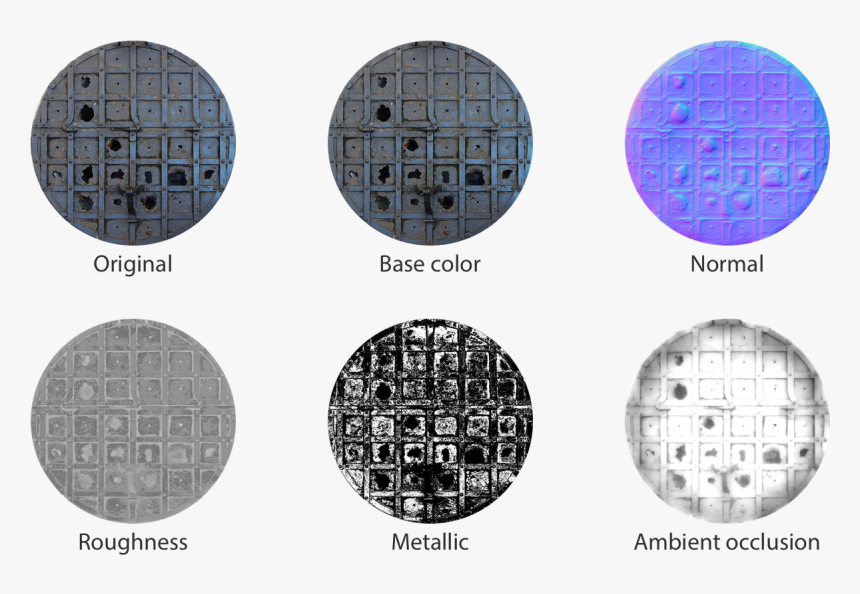

Phase Maps: Depict the distribution of different phases within the metal. This is particularly useful for understanding the composition and properties of alloys.

-

Grain Size Maps: Show the size and shape of individual grains within the metal. Grain size is a critical factor influencing the material’s strength and ductility.

-

Defect Maps: Highlight the presence of defects such as inclusions, pores, or cracks. These defects can significantly affect the material’s mechanical properties and performance.

-

Texture Maps: Illustrate the orientation of grains within the metal. Texture can influence the material’s response to stress and its susceptibility to fatigue.

Applications of Metallographic Maps

Metallographic maps find widespread applications in various fields, including:

-

Materials Science and Engineering: Understanding the relationship between microstructure and properties is fundamental to materials research and development. Metallographic maps play a crucial role in characterizing new materials, optimizing processing parameters, and controlling material properties.

-

Quality Control: In manufacturing, metallographic maps are used to ensure consistency in material quality and to identify potential defects that could compromise product performance.

-

Failure Analysis: When a metal component fails, metallographic maps can help determine the root cause of failure, such as fatigue, corrosion, or improper heat treatment.

-

Forensic Engineering: In legal investigations, metallographic maps can be used to identify the origin of materials and to determine if a component was manufactured according to specifications.

Benefits of Using Metallographic Maps

The use of metallographic maps offers numerous benefits:

-

Detailed Microstructural Insights: They provide a comprehensive visual representation of the metal’s internal structure, revealing details that are not visible to the naked eye.

-

Improved Material Understanding: By analyzing the map, engineers and scientists can gain a deeper understanding of the material’s properties and how they are influenced by its microstructure.

-

Optimized Material Selection and Processing: The information gleaned from metallographic maps can be used to select the most suitable material for a given application and to optimize processing parameters to achieve desired properties.

-

Enhanced Quality Control and Failure Prevention: By identifying potential defects early on, metallographic maps can help prevent product failures and ensure consistent quality.

FAQs about Metallographic Maps

Q: What is the difference between a metallographic map and a micrograph?

A: A micrograph is a single image taken under a microscope, while a metallographic map is a more comprehensive representation of the microstructure, often encompassing multiple images or sketches.

Q: What is the purpose of etching in metallographic sample preparation?

A: Etching selectively attacks different phases or constituents of the metal, creating variations in surface reflectivity that allow different features to be distinguished under a microscope.

Q: Can metallographic maps be used to analyze all types of metals?

A: Yes, metallographic maps can be used to analyze a wide range of metals, including ferrous, non-ferrous, and precious metals.

Q: How does the resolution of a metallographic map affect its usefulness?

A: The resolution of the map determines the level of detail that can be observed. Higher resolution maps are necessary for analyzing fine-grained structures or small defects.

Q: What are some of the limitations of using metallographic maps?

A: Metallographic maps are two-dimensional representations of a three-dimensional structure. They may not always accurately reflect the true distribution of phases or defects in the metal.

Tips for Creating and Interpreting Metallographic Maps

-

Use appropriate etching techniques: Select an etchant that effectively reveals the desired features of the microstructure.

-

Ensure proper sample preparation: Proper grinding and polishing are crucial for obtaining a smooth, reflective surface.

-

Use a microscope with sufficient resolution: The resolution of the microscope should be adequate to capture the desired level of detail.

-

Document the experimental conditions: Record all relevant information, such as the type of etchant, magnification, and lighting conditions.

-

Consult with experts: If you are unfamiliar with metallography, seek guidance from experienced metallurgists or materials scientists.

Conclusion

Metallographic maps are invaluable tools for understanding the microstructure of metals and alloys. They provide a wealth of information that can be used to optimize material selection, processing, and performance. By carefully creating and interpreting these maps, engineers and scientists can gain a deeper understanding of the relationship between microstructure and properties, leading to improved materials design and product reliability. As technology advances, the use of metallographic maps is expected to continue to play a crucial role in various fields, driving innovation and ensuring the safety and performance of metallic materials.

Closure

Thus, we hope this article has provided valuable insights into Mapping the Metallic Landscape: A Comprehensive Guide to Metallography. We thank you for taking the time to read this article. See you in our next article!